World’s Largest Aluminum-Lithium Aerospace Plant: world record in Lafayette, Indiana

Lafayette, Indiana, United States--Lafayette, Indiana, is home to the Casting House, an Alcoa (NYSE:AA) plant which will forge aluminum lithium alloys to be manufactured into wing skins, fuselage skins, wing stringers, floor beams and seat tracks for commercial jets built by Boeing, Airbus and Gulfstream; it's a massive warehouse on a 170-acre, multi-building plot that took $90 million and two years of construction to create and sets the world record for being the World’s Largest Aluminum-Lithium Aerospace Plant, according to the WORLD RECORD ACADEMY.

"Lafayette, Indiana, is now home to the world’s largest aluminum-lithium facility, a massive warehouse on a 170-acre, multi-building plot that took $90 million and two years of construction to create," the

CNBC says.

"Called the Casting House, the plant will forge aluminum lithium alloys to be manufactured into wing skins, fuselage skins, wing stringers, floor beams and seat tracks for commercial jets built by Boeing, Airbus and Gulfstream.

"The facility marks the latest installment in an aggressive push by Alcoa in aerospace. The company is doubling down on the massive industry, which pulls in roughly $120 billion each year in the U.S. alone. It’s pouring hundreds of millions of dollars into manufacturing facilities, including a $100 million jet engine parts facility that will focus on nickel alloys."

"Alcoa (NYSE:AA), a global leader in lightweight metals technology, engineering and manufacturing, has a giant aluminum-lithium plant in Lafayette, Indiana where it produces advanced, third-generation aluminum-lithium alloys for the aerospace industry. Aircraft manufacturers are increasingly turning to lighter and stronger aluminum-lithium alloys, which are less expensive than titanium and composites and enable better fuel efficiency and lower maintenance costs," the official website says..

"“The future of aviation is being built with aluminum-lithium, and Alcoa is making big moves to capture that demand,” said Klaus Kleinfeld, Alcoa Chairman and Chief Executive Officer. “This state-of-the-art facility positions Alcoa as the world’s premier aluminum-lithium supplier, offering the broadest portfolio of aluminum-lithium components for next generation aircraft.”

"The Lafayette facility is uniquely capable of making the world’s largest aluminum-lithium ingots—approximately 50 percent larger than the nearest competitor, and big enough to make any single-piece component on today’s aircraft. Complementing that capability, Alcoa operates the world’s widest, 220” rolling mill at its facility in Davenport, Iowa, making it the only company capable of producing single-piece aluminum-lithium wing skins for the largest commercial airplanes. Single-piece parts make structures stronger, lighter and less expensive because they minimize the number of complex joints."

"Alcoa employs approximately 3,200 people at three locations in Indiana, more than in any other US state," Alcoa.com says.

"Lithium is the world's lightest metallic element. When alloyed with aluminum and other metals, the material provides an outstanding combination of strength, toughness, stiffness, corrosion resistance, and high-temperature performance, and at a lower cost than titanium or composites.

"Alcoa supplies aluminum-lithium products to all major airframe manufacturers. Beyond aviation, Alcoa supplies aluminum-lithium products for:

- Space applications, including on the ULA rocket and developing applications for Space X;

- Automotive applications, including parts for commercial trucks, high-performance sports cars and Formula One cars; and

- Military applications."

Alcoa’s aluminum-lithium materials:

- lower the weight of single-aisle fuselage applications by up to 10 percent versus composites;

- lower the cost to manufacture, operate and maintain planes by up to 30 percent versus composite-intensive airplanes, and at significantly lower production risk;

- contribute to 20 percent better fuel efficiency; and

- deliver passenger comfort features equivalent to composite-intensive planes, such as higher cabin pressure, large windows and higher humidity.

"Alcoa's new $100-million, 115,000-square-foot plant will produce more than 44 million pounds of aluminum-lithium for the production of airplanes, according to the manufacturer," the Journal and Courier says.

"The Indiana Economic Development Corp., the city of Lafayette and Tippecanoe County provided various tax incentives totaling more than $6 million for the project to come together.

"Alcoa, which has been in business for more than 125 years, opened its Lafayette operation in 1937. The company employs 60,000 in 30 countries."

"The world's largest production plant for light alloy materials for the aerospace industry opens its doors today in Lafayette.

"Alcoa's new $100-million, 115,000-square-foot plant will produce more than 44 million pounds of aluminum-lithium for the production of airplanes, according to the manufacturer," the Indiana Economic Digest says.

"The Indiana Economic Development Corp., the city of Lafayette and Tippecanoe County provided various tax incentives totaling more than $6 million for the project to come together.

"It's the largest facility of its kind in the world," said Holly Gilham, a spokeswoman for the Indiana Economic Development Corp.

"Alcoa officially opened the world’s largest aluminum-lithium plant in Lafayette, Ind., where it will produce advanced, third-generation aluminum-lithium alloys for the aerospace industry," the Industrial Heating reports.

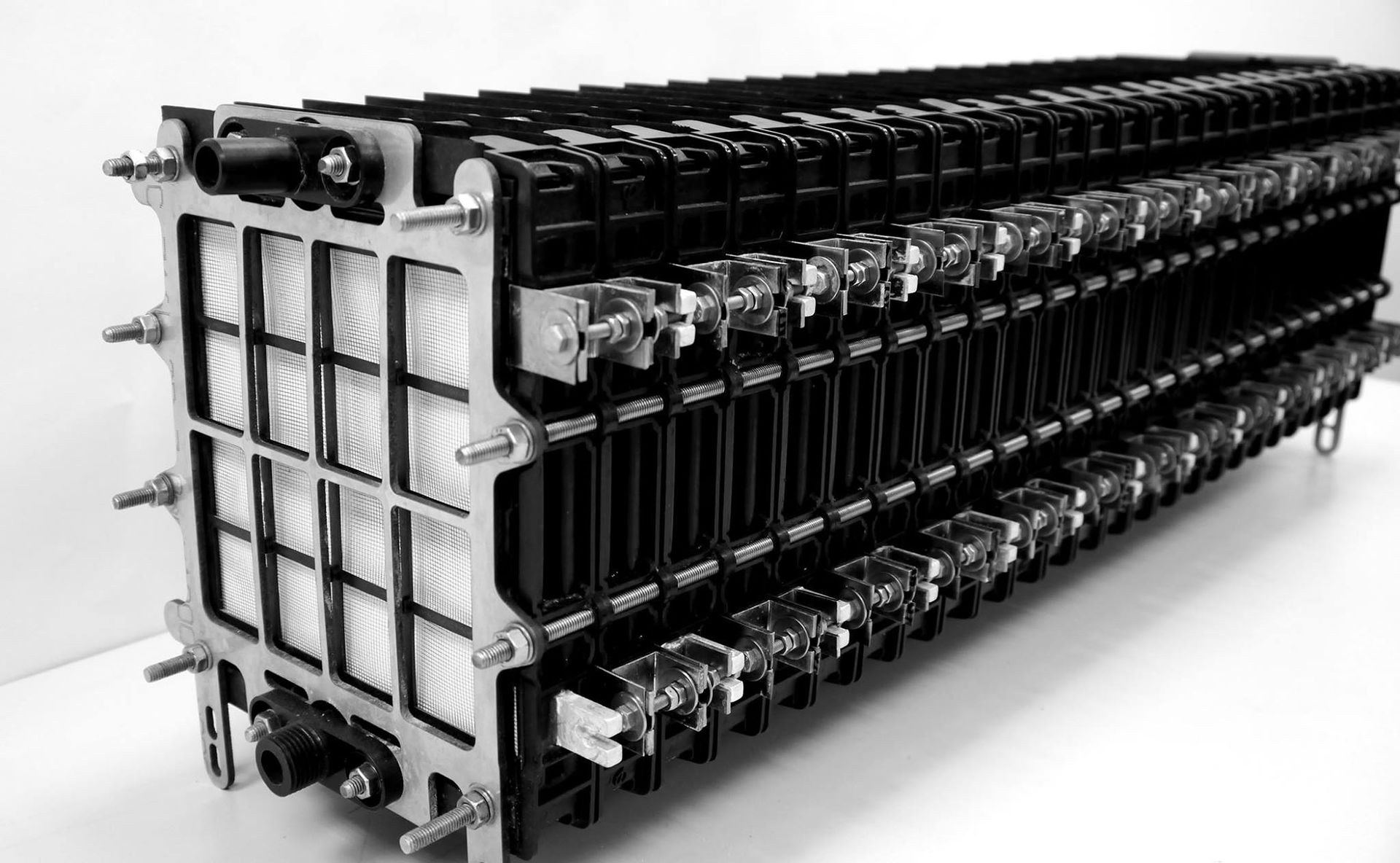

"The Lafayette cast house can produce more than 44 million pounds of aluminum-lithium annually. Alcoa’s materials scientists invented a majority of the alloys produced at the facility as well as the casting equipment and processing technology. The company offers a complete portfolio of aluminum-lithium products, including extruded, forged and rolled parts.

"In other news, Alcoa recently produced the world’s largest single-piece forged aluminum hull for combat vehicles to improve troop protection as part of a joint initiative with the U.S. Army launched in 2013. Alcoa manufactured the single-piece part, which was co-designed by Alcoa and the U.S. Army Research Laboratory, with the goal of replacing today’s assembled hulls."