World's first commercial fluid catalytic cracking plant: world record in Baton Rouge, Louisiana

Baton Rouge, Louisiana, United States--ExxonMobil's Baton Rouge Refinery in Baton Rouge, Louisiana, the fifth-largest oil refinery in the United States and thirteenth-largest in the world, is the site of the first commercial fluid catalytic cracking plant that began processing at the refinery; the World's first commercial fluid catalytic cracking plant (known as the Model I FCC) began processing 13,000 barrels per day (2,100 m3/d) of petroleum oil in the Baton Rouge refinery on May 25, 1942; in 1963, that first Model I FCC unit was shut down after 21 years of operation, according to the WORLD RECORD ACADEMY.

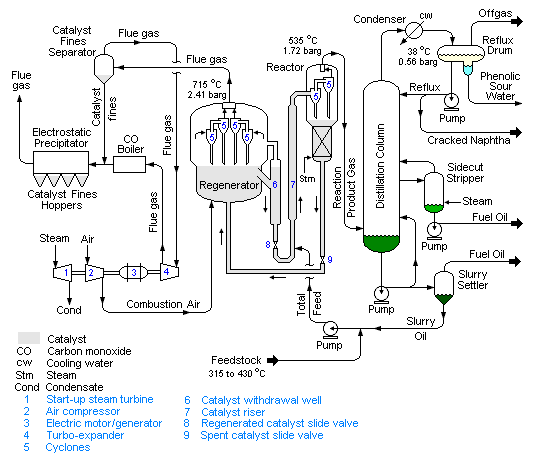

"Fluid Catalytic Cracking (FCC) is the conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of petroleum (crude oils) into gasoline, alkene gases, and other petroleum products. The cracking of petroleum hydrocarbons was originally done by thermal cracking, now virtually replaced by catalytic cracking, which yields greater volumes of high octane rating gasoline; and produces by-product gases, with more carbon-carbon double bonds (i.e. alkenes), that are of greater economic value than the gases produced by thermal cracking.

"Based on the success of the pilot plant, the first commercial fluid catalytic cracking plant (known as the Model I FCC) began processing 13,000 barrels per day (2,100 m3/d) of petroleum oil in the Baton Rouge refinery on May 25, 1942, just four years after the CRA consortium was formed and in the midst of World War II. A little more than a month later, in July 1942, it was processing 17,000 barrels per day (2,700 m3/d). In 1963, that first Model I FCC unit was shut down after 21 years of operation and subsequently dismantled.

"In the many decades since the Model I FCC unit began operation, the fixed bed Houdry units have all been shut down as have most of the moving bed units (such as the TCC units) while hundreds of FCC units have been built. During those decades, many improved FCC designs have evolved and cracking catalysts have been greatly improved, but the modern FCC units are essentially the same as that first Model I FCC unit." (Wikipedia)

"ExxonMobil's Baton Rouge Refinery in Baton Rouge, Louisiana is the fifth-largest oil refinery in the United States and thirteenth-largest in the world, with an input capacity of 540,000 barrels (86,000 m3) per day as of January 1, 2020. The refinery is the site of the first commercial fluid catalytic cracking plant that began processing at the refinery on May 25, 1942.

"Standard Oil first erected the refinery in 1909. Today's facility is part of a complex made of nine individual plants across the region. The main plant is located on the east bank of the Mississippi River. There are about 6,300 workers spread across these sites, including 4,000 direct employees (the rest are contractors).

"In 2013 Genesis Energy LP announced an investment of $125 million to improve ExxonMobil's existing assets in the Baton Rouge area. The investment includes plans to build an 18-mile (29 km), 20-inch (51 cm) diameter crude oil pipeline that connects Genesis Energy's Port Hudson terminal, to ExxonMobil's Baton Rouge refinery. The Baton Rouge refinery's tank farm has a capacity of 540,000 barrel-per-day (bpd)." (Wikipedia)

"This booklet commemorates the designation of The Fluid Reactor as a National Historic Chemical Landmark. The designation was conferred by the American Chemical Society, a not-for-profit scientific research and educational organization of more than

155,000 chemists and chemical engineers. Plaques marking the designation were presented to Exxon on November 3, 1998, for

installation at the Baton Rouge Refinery and the Louisiana Arts and Science Center," The

American Chemical Society says.

"The citation reads: PCLA #1 (Powdered Catalyst Louisiana), went on stream on May 25, 1942, in the Baton Rouge Refinery of the Standard Oil Company of New Jersey (now Exxon Corporation). This first use of powdered catalysts in continuous operation allowed the efficient cracking of heavy gas oils to meet the growing demand for high-octane fuels. PCLA #1 was dismantled in 1963 after 21 years of successful operation. Today, more than 350 fluid bed reactors, including PCLA #2 and PCLA #3, are in use worldwide for the manufacture of fuels, chemical intermediates, and plastics.

"After the war, demand for gasoline to fuel automobiles continued to increase. Today, more than 370 fluidized FCC units are in operation around the world. The FCC capacity in the US increased from 50 million gallons per day in 1950 to over 210 million gallons per day in 1992. Over the same time period, world capacity is over 460 million gallons per day, up from 63 million gal-

lons per day. As the demands for gasoline volume and qualities have changed, the incorporation of new catalyst technology in these versatile fluidized catalyst units has enabled fuels manufacturers to provide cleaner burning gasolines."

"At 2:25 a.m. on May 25, 1942, history was made when oil was charged to PCLA No. 1, Model I, in Standard Oil of New Jersey’s Baton Rouge, Louisiana, refinery. This event was the culmination of years of collaboration between companies in the oil, chemical, engineering and catalyst industries," the

W.R. Grace says.

"In October 1938, Standard Oil of New Jersey, Standard Oil of Indiana, Anglo-Iranian Oil Co., Ltd., Royal Dutch-Shell Co., The Texas Co., M. W. Kellogg, Universal Oil Products Co. (UOP) and I. G. Farben organized Catalytic Research Associates (CRA) to develop a cracking process that would produce high yields of gasoline and not infringe existing fixed-bed catalytic cracking process patents. More than 1,000 technical experts worked on the project and it was described as the “greatest scientific effort directed to a single project” before radar and the Manhattan Project.

"Davison Chemical (later to become W. R. Grace & Co.) had been working on a broad program of “powdered catalyst” since 1936, and entered into an agreement with Standard Oil Development Company in 1938. In 1940, Grace produced catalyst at pilot plant scale for use in the initial 100-barrel/day experimental fluid catalytic cracking (FCC) plant. With the entry of the United States into World War II, construction of a commercial plant for production of FCC catalyst at Grace’s Curtis Bay, Maryland, plant was authorized on December 18, 1941, and the first commercial quantity of FCC catalyst was produced at the plant on May 9, 1942. The timeline for development was incredibly quick, spurred by the urgency of the wartime need for higher-octane fuel. Concept to commercialization took only a few years (1938-1942). By 1945, 34 FCC units had started up and were supplied by Grace."

"The first commercial FCC unit was built by The M W Kellogg Company in Standard Oil of New Jersey’s Baton Rouge, Louisiana, refinery and commissioned in May 1942. Between 1942 and 1944, Kellogg built 22 of 34 FCC units constructed throughout the US, and the FCC process quickly became a major contributor to worldwide propylene and butylene production," the

Digital Refining says.

"Rare earth-exchanged Y zeolite catalyst was first synthesised by Mobil in 1959. By the late 1960s, over 90% of US FCC units were operating with the Mobil-invented zeolite catalyst. The high activity of the zeolite catalysts, compared to the earlier amorphous catalysts, greatly improved the gasoline yield and reduced coke and dry gas yields from the FCC units, but the catalyst’s high hydrogen transfer characteristic greatly reduced the light olefin yield and gasoline octane.

"In the 1970s, after the introduction of zeolite catalyst, FCC unit design and operation evolved to regain some of the lost octane and light olefin yield, primarily with a higher reactor operating temperature and riser cracking.2 Increasing reactor temperatures increased the light olefin yield, but this came at the expense of an increased yield of dry gas — a lower-valued FCC product."

"Exxon Mobil Corp (XOM.N) plans to complete an overhaul of a gasoline-producing fluidic catalytic cracker (FCC) at its 502,500 barrel-per-day (bpd) Baton Rouge, Louisiana, refinery by April 5, sources familiar with plant operations said,"

Reuters reports.

"Exxon shut the 110,000-bpd PCLA 3 FCC on Feb. 25 for the overhaul, which was scheduled to take seven weeks to complete.

"The firm also plans to shut in April a 45,000-bpd diesel hydrotreater for planned work that will last until mid-June, the sources said. PCLA 3 is one of two 110,000-bpd FCCs at the refinery."

"In 1938, a consortium called Catalytic Research Associates (originally Standard Oil of New Jersey, Standard Oil of Indiana, M. W. Kellogg Co., and I. G. Farben) set out to develop a new cracking process.9 At the beginning of the 2nd World War, I. G. Farben was dropped from the Consortium, and Anglo-Iranian Oil Co. Ltd, Royal Dutch-Shell Co., The Texas Co. and Universal Oil Products Co. (UOP) joined," the RCS Publishing says.

"A pilot plant based on a powdered catalyst moving through a pipe coil reactor and a regenerator was built in Baton Rouge (LA, USA). The 100 barrels per day unit was called PECLA-1 (Powdered Experimental Catalyst, Louisiana). In about a year, the system was developed to commercial stage, and mid-1942, the first commercial FCC unit (PCLA-1) was started up.9,10 This system was based on an up-flow reactor and regenerator11 and used a clay-based catalyst.9 It was based on work of Lewis and Gilliland,12 working with Standard Oil Company of New Jersey, who suggested that a low velocity gas flow through a powder might “lift” it enough to cause it to flow in a manner similar to a liquid.

"The system was extremely successful, and with ongoing developments,14 at the end of the war, 34 FCC units were in operation in the USA. PCLA No. 3, which was the second unit at Baton Rouge, was started up in June, 1943. This unit is still in operation today, and is the oldest operating FCC unit, as the PCLA-1 unit was shut down in 1963."

"In the early 1900s, Standard Oil Company of New Jersey sought to strengthen its position in the southern United States. After considering several locations, the company chose a location high on the bluffs of the Mississippi River in North Baton Rouge. In April 1909, Standard Oil Company of Louisiana was chartered, and by November 1909 the refinery processed its first products," the ExxonMobil says.

"Since that time, ExxonMobil Baton Rouge has been essential to the economic, political, and social landscape of the community. We provide quality jobs, provide technologically innovative products and engage with the community to make it a great place to work and live.

"Operational excellence and improved energy efficiency are responsible for Baton Rouge's ever-increasing output capacity. Our versatile integrated facilities produce gasoline, diesel, jet fuel, aviation fuel, lubricating oils and waxes. In addition, products produced at the Chemical Plant, along with the Resins Finishing, Polyolefins and Plastics plants, are used to make products people use every day, including lightweight car and appliance parts, paint, adhesives, plastic milk jugs, plastic films, synthetic rubber, and diapers."

Photos: World's first commercial fluid catalytic cracking plant: world record in Baton Rouge, Louisiana

(1) Wikipedia

(2) Wikipedia

(3) Facebook/KBR

(4) Baton Rouge Business Report

(6) ExxonMobil

(7) ExxonMobil

(8) ExxonMobil

(9) ExxonMobil